Steel sheets normally range in thickness from 1/16 inch to 3/16 inch, while steel plates include thicker materials varying from 3/16 inch to a number of inches thick. Comprehending the residential properties, kinds, and applications of steel sheets and plates is necessary for designers, designers, and makers who depend on these materials for their projects.

One of the most usual types of steel sheets is hot-rolled steel, which is created by rolling steel at high temperatures, making it less complicated to form and form. In addition, there are specialized steel sheets, such as galvanized steel, coated with a layer of zinc to give improved corrosion resistance, making it ideal for outside applications, consisting of roof covering and exterior siding.

Steel layers come in different grades, consisting of structural, marine, and abrasion-resistant, each with certain residential or commercial properties customized for different environments and tons. The selection of the proper grade and kind of steel sheet or plate is essential for making certain the safety, efficiency, and longevity of the last product.

The manufacturing of steel sheets and plates includes substantial processes including cutting, flexing, welding, and ending up. Welding is another necessary procedure in the assembly of steel structures, needing expertise of different welding methods such as MIG, TIG, and stick welding. The ending up procedure may include surface area therapies and layers that enhance the material's resistance to rust, boost visual appeals, and extend solution life.

Using steel sheets and plates has evolved with developments in modern technology, leading to developments such as high-strength low-alloy steels, which supply equal mechanical properties to conventional grades while minimizing weight. These innovative products enable greater style versatility, lowering the demand for large and hefty parts, and can bring about cost savings in material usage and transportation. Composite products that include steel sheets as a component of multi-material systems have actually additionally arised, enhancing performance in particular applications, particularly in the aerospace and automobile industries. The consistent r & d in the metallurgy of steel are concentrated on developing lighter, more powerful, and extra corrosion-resistant products, which will certainly further expand the convenience and applications of steel sheets and plates in numerous sectors.

Sustainability is an increasingly vital factor to consider in the production and usage of steel sheets and plates. Steel recycling has been an indispensable part of the industry for years, and the majority of brand-new steel created comes from recycled products.

The building and construction market heavily depends on steel sheets and plates for creating durable frameworks that can hold up against diverse environmental pressures. In structural applications, the strength-to-weight proportion of steel allows for slim styles that do not compromise on safety and security or performance. Steel plates offer as vital components in bridge building and construction, with engineers creating steel plate girders to support hefty loads and period cross countries. Additionally, steel sheets are thoroughly used in putting up steel structures, giving flexibility in layout while guaranteeing conformity with building ordinance and safety and security requirements. The building and construction of skyscrapers and huge click here industrial sheds exhibits the synergetic partnership between steel sheets and plates and modern-day architectural techniques.

In the manufacturing field, steel sheets and plates form the foundation of a substantial number of items. From devices to automobiles, the demand for durable and dependable materials is critical. Automotive makers utilize high-strength steel sheets to create body panels that are light-weight yet unbelievably resilient, which adds to boosted fuel effectiveness without giving up safety. Likewise, the home appliance sector gain from cold-rolled sheets with improved surface area coatings, ensuring aesthetic charm while giving long-lasting sturdiness versus everyday wear and tear. The combination of steel sheets in tools and equipment not only improves the capability of products but likewise expands their lifecycle, providing considerable value to consumers and producers alike.

On a much more customized note, the oil and gas sector's demand for steel plates is driven by the construction of pipelines and storage space centers that have to sustain extreme atmospheres and pressures. The needs for these products dictate that they possess high resistance to both corrosion and mechanical anxiety. Steel plates utilized in these applications are commonly made to exacting standards, ensuring they can endure the rigors of transport and storage space of varied materials, consisting of petroleum and gas. Additionally, offshore drilling platforms are surrounded by harsh marine conditions, necessitating making use of marine-grade steel plates that make certain architectural integrity and safety.

Past commercial applications, the visual usage of steel sheets has located a home in building style. The use of corten steel, known for its rustic aging, is specifically preferred in developing outside sculptures and developing facades that mix right into natural environments, showcasing the adaptability and appeal of steel in different design ideologies.

Several variables need to be considered to guarantee your tasks proceed efficiently when it comes to picking vendors for steel sheets and plates. The credibility of the supplier, item variety, quality guarantee processes, lead times, and consumer service are important components in choosing a partner. Several makers likewise require certain accreditations, such as ISO 9001, to ensure that distributors satisfy international top quality administration criteria. Moreover, the availability of value-added solutions, such as pre-fabrication and machining, can improve project timelines, supplying extra value to contractors and suppliers.

As we look toward the future, the function of steel sheets and plates will likely pivot in response to emerging modern technologies and materials scientific research. Innovations such as 3D printing, which has actually started to infiltrate typical manufacturing worlds, might provide means to new applications for steel products and compounds. Furthermore, innovations in smart products that respond to environmental stimulations could cause the growth of self-healing steel or materials with improved efficiency features. The overall pattern towards modular construction is most likely to further highlight the relevance of steel sheets and plates, as standardized elements develop efficiency in assembly and minimize on-site construction time.

In final thought, steel sheets and plates are essential materials that develop the structure for countless applications across a diverse variety of sectors. From their essential role in building and making to their visual contributions to modern design, these flexible products remain to evolve in reaction to sustainable methods and technical innovations. As sectors pursue development and environmental obligation, the relevance of understanding and picking the appropriate steel sheets and plates will stay essential to attaining useful, cost-efficient, and sustainable engineering services. Whether you are a home builder, maker, or developer , acknowledging the essential function of steel in your jobs will not only improve performance however likewise contribute to the durability and sustainability of our constructed setting. As we move on, it is clear that steel sheets and plates will certainly remain to form the future of design and design in ingenious and interesting methods.

Luke Perry Then & Now!

Luke Perry Then & Now! Freddie Prinze Jr. Then & Now!

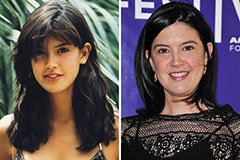

Freddie Prinze Jr. Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Batista Then & Now!

Batista Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!